Automated Tactical Ammunition Classification System (ATACS)

Working closely with the Defense Ammunition Center (DAC) in McAlester, Okla., Cybernet created the first-ever ATACS system, an innovative system built within less than 90 days for rapid fielding in the Iraqi theater of operation.

This innovative system is designed to:

- Inspects over 5,000 rounds per hour, depending on round mix;

- Sort and inspect 5.56 mm, 7.62 mm, 9 mm, .45 caliber and .50 caliber ammunition;

- Learn new calibers/types of rounds;

- Inspect chambering dimensions including length, concentricity, diameter, head stamp, primer seating, etc.;

- Detect defects such as dents, perforations and corrosion; and

- Separate spent brass from live ammunition.

ATACS is currently in operation at Camp Arifjan, Kuwait in support of Operation Iraqi Freedom. ATACS units are also deployed at Fort Irwin and Fort Bragg, with additional units in production. ATACS is transportable to remote unimproved sites; reduces the manpower needed to handle loose, broken lot ammunition; reclaims serviceable ammunition for training use; is a field-proven technology: and provides faster, more consistent inspection and re-qualification of ammunition.

Over the years, the ATACS program has developed into an entire family of ammunition handling products, with applications ranging from single-round tabletop inspection units to round assembly machines.

Spent Brass Sorter (SBS)

Spent Brass Sorter (SBS)

Projectile Identification System (PIDS)

A “barcode scanner” for large caliber munitions. It identifies and inspects munitions by shape, color coding, optical character recognition, and code reading – making it ideal for load assurance of proper round types.

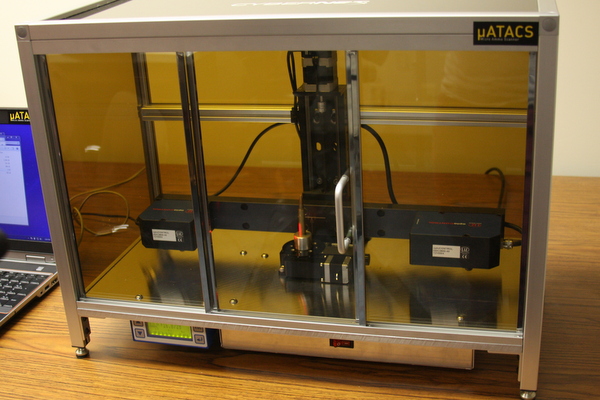

Micro Automated Tactical Ammunition Classification System (µATACS)

A table-top machine that performs single cartridge or round profile capture and comparison to as-manufactured 3D dimensional standards for round type. It is ideal for single round optical chambering tests, or tests supporting munitions manufacturing process quality control.

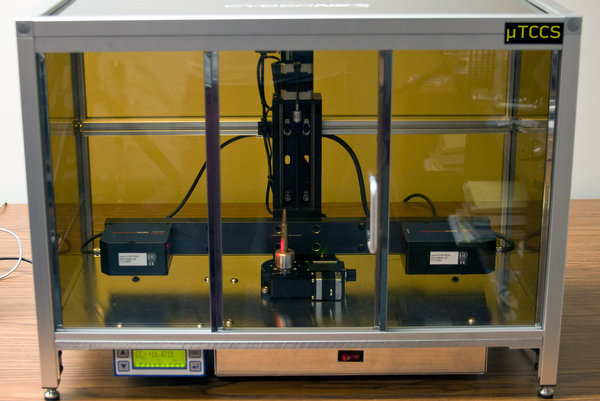

Micro Tactical Cartridge Capture System (µTCCS)

A “barcode scanner” for large caliber munitions. It identifies and inspects munitions by shape, color coding, optical character recognition, and code reading – making it ideal for load assurance of proper round types.

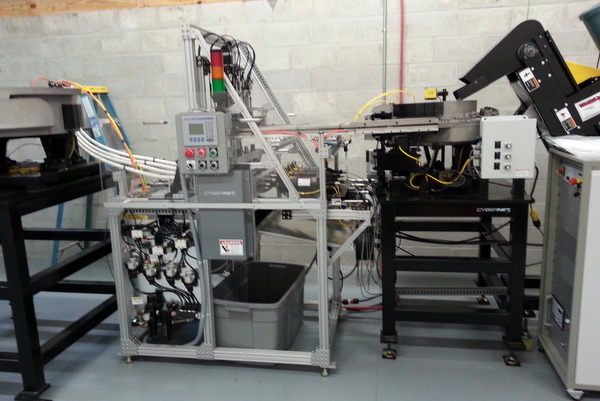

Agile Multiple Caliber Assembly (AMCAL)

Agile Multiple Caliber Assembly and Loading Line (AMCAL) manufactures small arms munitions ranging from 4mm to 50 caliber with simple reconfiguration of a common manufacturing core.

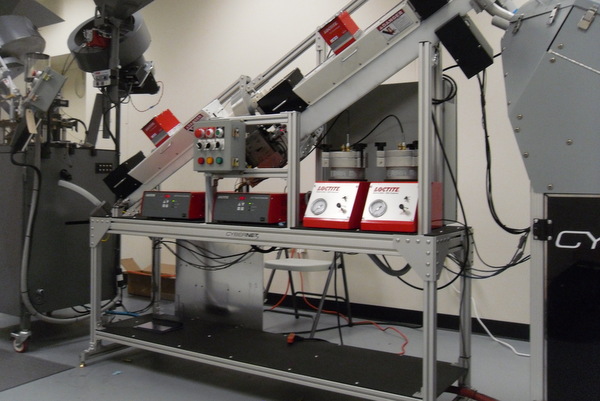

Multiple Caliber Sealing Machine (MCSM)

Multiple Caliber Sealing Machine (MCSM) applies and cures sealant to ammunition in sizes from 4mm to 50 caliber with simple reconfiguration of the holder belt assembly and reprogramming for sealant-specific application and curing.

Multiple Caliber Polymer Case Assembly Machine (MPCAM)

Multiple Caliber Polymer Case Assembly Machine (MPCAM) builds two part polymer (plastic) cases for munitions ranging in size from 4mm to 50 caliber with simple reconfiguration of a common manufacturing core.